The ARC Process…

INSPECTION

Our process begins by removing the tyres, weights and valves. We inspect the wheels for cracks, buckles, corrosion and kerb damage. If additional remedial work is required, we will advise the customer at this stage.

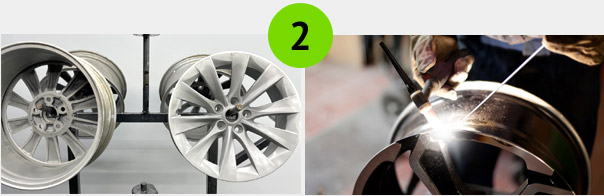

STRIPPING & REPAIRING THE WHEEL

The wheels are chemically stripped to remove old paint and lacquer and any other unwanted contaminates. Any repairs that are required to restore the wheel to its original state through welding, buckle repair or sandblasting to remove corrosion are carried out at this stage.

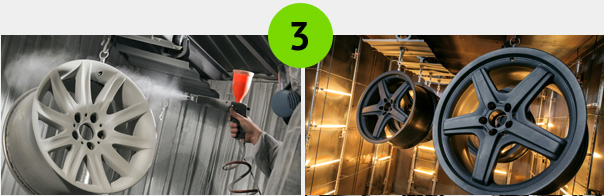

PRIME & PAINT

The wheels are prepared for painting and then powder coat primer is applied. The wheels are transferred to the oven and baked at 180 degrees for 18 minutes. The wheels are then removed from the oven and let cool to 100 degrees approximately. They are then sprayed with the base colour as specified by the manufacturer or to the customer’s preference.

We have one of the largest selections of OEM Tier 1 Alloy Wheel Paints meaning that we can provide our customers with an exact match for an original paint colour or a bespoke colour option. Immediately after the base colour is applied a high gloss powder lacquer is then sprayed on to seal the wheel and it is returned to the oven for another bake.

DIAMOND CUTTING

If the wheel requires a diamond cut finish it is then mounted to our lathe machine and skimmed to precision which also removes any marking that may be on the bare metal. Lacquer is then applied to seal the diamond cut finish and then the wheel is returned to the oven for its final bake.

QUALITY CONTROL

Finally, each wheel is carefully inspected by a senior engineer to ensure the finish is as close to the original factory finish as possible. The new or existing tyres together with new weights and valves are refitted to the refurbished wheels and then the wheels are balanced.